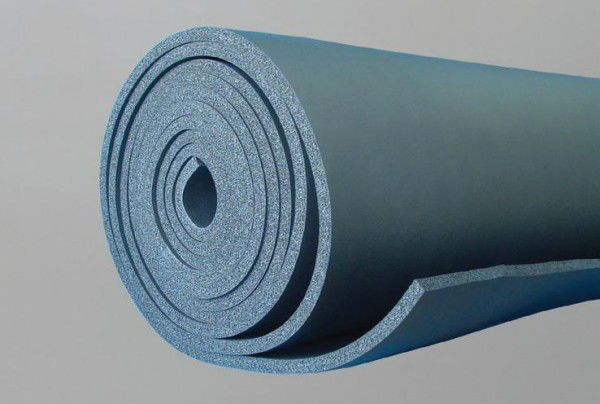

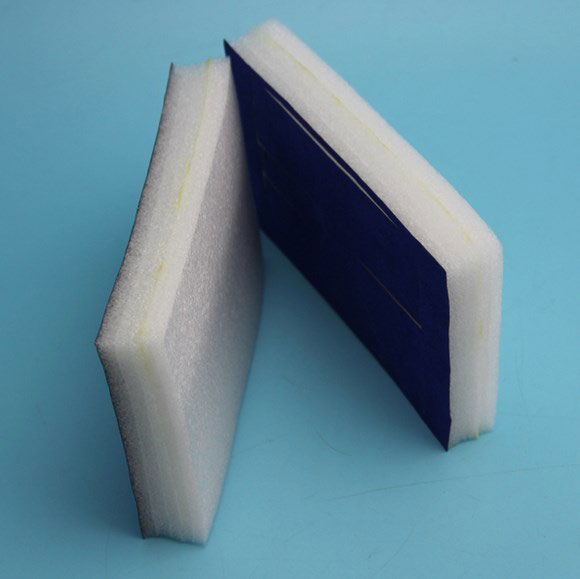

Packaging Foam: This is an environment friendly packing material with high anti-impact function. Its raw material is PE. The entire raw material of PE Foam production is physical change; therefore PE is non-toxic and environmental benefit. It also can add anti-static function according to customer’s requirement. The surface resistance value is 108-1011 Ohm. Its surface also can print product illustration, company LOGO, anti-static symbol and so on.

Usage:

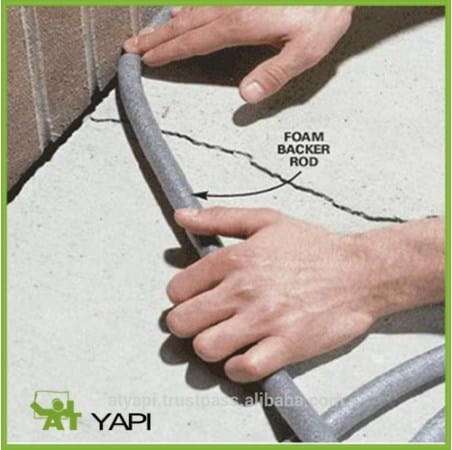

It is widely used in packing electric appliances, household appliances, mechanical parts, glass, wood furniture, handicrafts, ceramics and construction area.

1) Tasteless and non-toxic.

2) Light weight, good flexibility and cushioning.

3) Low thermal conductivity and superior heat insulation

4) Outstanding waterproof and anti-corrupt capability.

5) Thickness and size can reach customers’ requirements.

6) Customized printing available

Polyethylene is the ideal medium with which to accomplish these tasks since the material is both durable and resistant to environmental hazards. In fact, polyethylene packaging is considered superior to any other material for this purpose and its use is widespread in the flexible packaging market.

What makes polyethylene packaging so reliable is its molecular structure. Its cellular makeup is so cross-linked that it is virtually impossible for water vapor to pass through. This also makes polyethylene packaging resistant to damage from coming into contact with chemicals or solvents, as well as being able to withstand friction. Of course, there are varying grades of polyethylene, ranging from very high density to low density and high molecular weight. Each type of polyethylene provides unique properties, such as elasticity, impermeability, clarity, or high tensile strength.