Physically Cross-Linked Polyethylene Foam Crosslinked Details

Physically cross-linked polyethylene foam that can be produced with advanced technology, have superior mechanical properties and an advanced dimensional stability. The product is extruded with the help of additives and lasteners which is followed by the electron beam process. After the electron beam process with hot oven operation the physical characteristic of the product increases by means of dilatation, and a product with a very closed-cell structure and a smooth surface is obtained. It can be produced for different sectors in cut plate, roll, tube, extra-laminated or non-laminated forms.

Production Standard

| Production Standard | |

|---|---|

| Thickness and Density – Single fold: | 1 mm> 67-200 kg/m3 2-5 mm> 28-200 kg/m3 6-10 mm> 28-100 kg/m3 |

| Thickness Multi-Fold: | 10-150 mm (Lamination cannot be made for materials having higher density than 145 kg/m3 ) |

| Roll Width: | 800-1500 mm |

| Roll Length: | 25/75/50/100/150/200 m |

| Plate Width: | – |

| Plate Length: | – |

| Color: | Natural/Anthracite/White/Gray |

| Fire Resistance: | FMVSS 302/ ISO 11925-2 |

| Anti-static: | Can be produced upon request |

| Composite: | Metalized Film, aluminum film, Adhesive Tape Film Lamination |

| Waiting Period: | There is no waiting period. |

| Packaging: | *Standard *Stretch Film wrapped *Nylon Pouch |

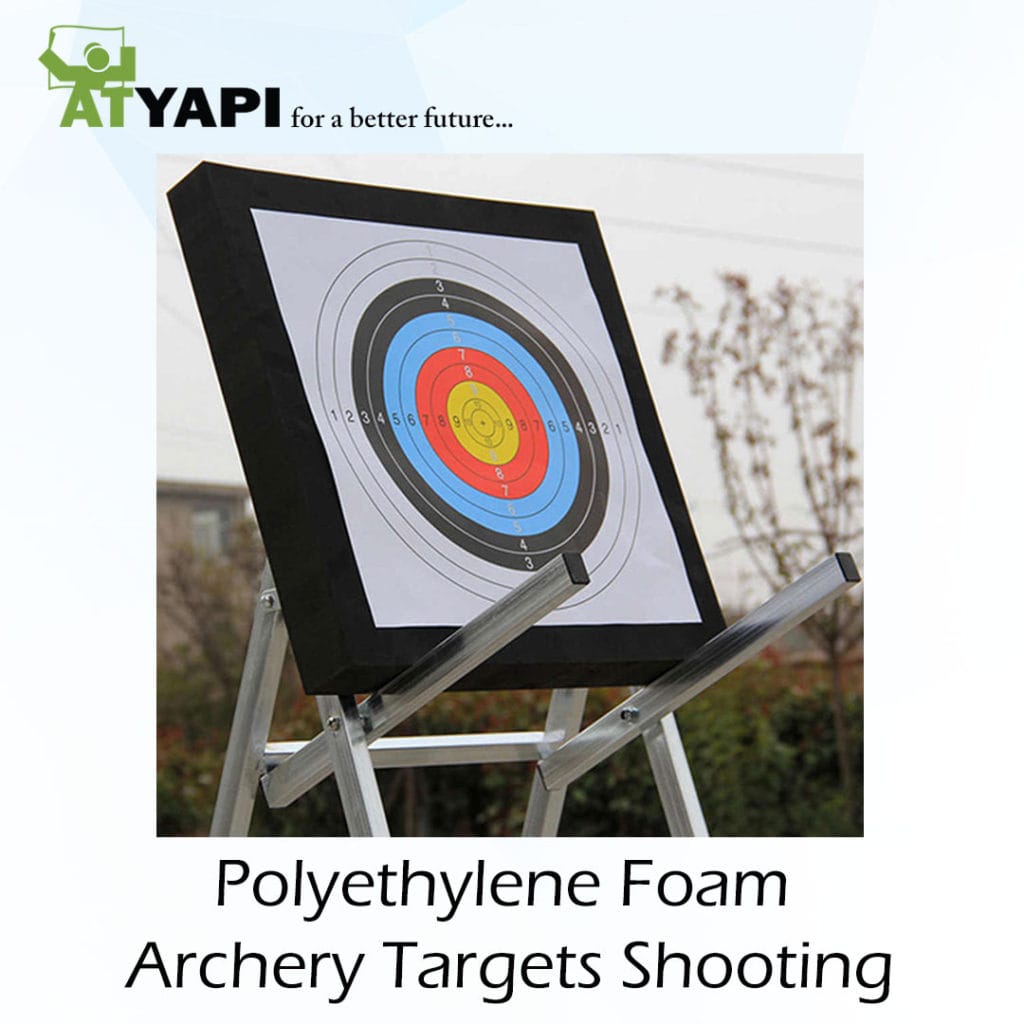

Physically Cross-Linked Polyethylene Foam Gallery